We are excited to announce that VHS Hydraulic Components and our sister

company Neilson Hydraulics have been appointed the official UK distributor for

IMO that provides a wide range of slew drives and slewing rings, which can be

used in a variety of applications.

IMO is a

specialist in turning and slewing solutions. Since 1988, IMO has been

developing and producing IMO Slew Drives and Slewing Rings for the most varied

of application areas. The company has two production locations in Gremsdorf in

the Nuremberg metropolitan region in Germany.

For more than 30 years, IMO antifriction bearing solutions have been impressing

customers throughout the world with their excellent technology, high quality,

and the customer proximity of the company. However, the slewing ring specialist

focuses on custom bearing solutions. In close collaboration with the customer,

we develop tailored slew drives and slewing rings in order to fully exploit the

potential of the applications at hand.

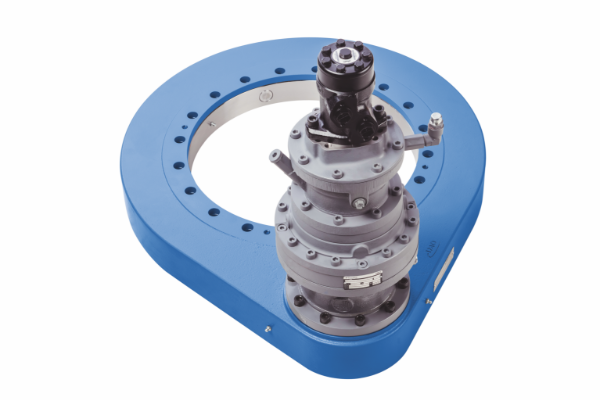

What is a slew

drive?

A Slew Drive is a ready-to-install

unit consisting of a ball or roller slewing ring for the simultaneous transfer

of axial and radial forces as well as tilting moments with hydraulic or

electric drives in a completely enclosed housing.

·

Spur gear unit or worm

drive

·

Max. torques of up to 450

kNm

·

Max. tilting moment load

of up to 1,200 kNm

·

Raceway diameter of up to

approx. 1,000 mm

·

Unlimited slewing range

·

Fast installation

·

Smooth, jolt-free movement

- no stick/slip effect

·

Maximum safety through

full encapsulation

·

Cost-efficient, proven

technology

·

Compact, space-saving,

heavy duty

For Slew Drives, some

attachments such as the brake, planetary gear, motor, and rotary encoder can be

delivered on request.

Standard product or

individual solution?

IMO Slew Drives are available

as a large selection of standard series. If none of the IMO standard solutions are

suitable for your application, our application engineers can work with you to

develop a custom slew drive. Versions for continuous operation and extreme

temperatures are possible, as are special materials. The mounting structure

such as valve blocks, hydraulic connections, adapter plates, and sensors can

also be taken into account in the design.

IMO Slew Drives can be used in a variety

of applications

IMO Slew Drives are

designed for a long lifetime with low maintenance efforts. They require a small

amount of installation space but can take top loads. That is why they are

the top slewing solution for lots of applications. IMO Slew Drives are used in

forestry, agriculture, mining, manlift platforms, numerous maritime

applications, and machine construction and plant engineering.

FIND YOUR IDEAL IMO SLEW

DRIVE AT VHS HYDRAULIC COMPONENTS

The IMO Slew Drive WD Series

features:

·

High rotational speed

·

High gear ratio

·

Rotational speed 1-3 rpm

IMO Slew Drive WD-L features:

·

Raceway diameter 156 mm to 713 mm

·

Maximum tilting moment 9 kNm to 1,095 kNm

IMO Slew Drive WD-H features:

·

Raceway diameter 280 mm to 725 mm

·

Maximum tilting moment 94 kNm to 1,052 kNm

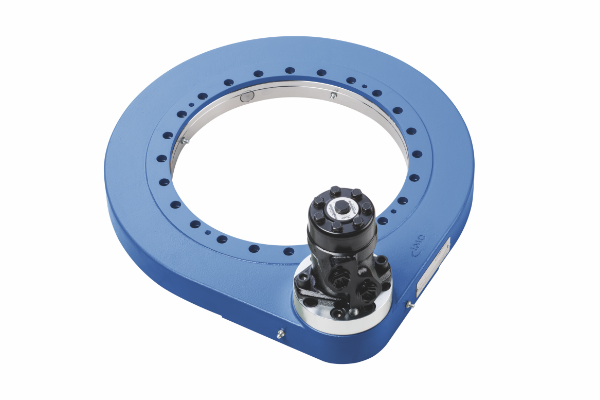

The IMO Slew Drive SP Series features:

·

Higher rotational speeds

·

Higher duty

IMO Slew Drive SP-I features:

·

Raceway diameter 229 mm to 1091 mm

·

Maximum tilting moment 22 kNm to 353 kNm

IMO Slew Drive SP-H features:

·

Raceway diameter 455 mm to 955 mm

·

Maximum tilting moment 153 kNm to 562 kNm

IMO SLEWING

RINGS FOR INDUSTRY AT VHS HYDRAULIC COMPONENTS

What is a Slewing Ring?

Slewing Rings are large diameter antifriction bearings for the

simultaneous transmission of axial and radial forces as well as tilting

moments. They replace traditional solutions with fixed and floating bearings as

well as king pin bearings. Frequently, this results in bearings with

axial/radial bearing combinations with one bearing point. This can

significantly simplify the design of the mounting structure and the

installation of the bearings, which in turn reduces effort and costs.

Cost-effective and tried-and-tested, IMO antifriction bearings are

available as:

·

Ball slewing rings, roller slewing rings, and

ball-roller combination slewing rings

·

Four-point bearings, double four-point

bearings/eight-point bearings, flange bearings, wire race bearings, cross

roller bearings

·

Segmented slewing rings

·

Gear rims

·

External gearing, internal gearing, or without

gearing

·

Diameter ranging from 100 mm to 6000 mm

·

With cages (steel, brass, or plastic) or spacers

(brass or plastic)

·

With standard seals or specially produced

special seals

·

Optionally with induction-hardened raceways

·

Different corrosion protection coatings possible

IMO Slewing Rings have mounting holes and a sealed raceway system with

grease lubrication. They can be combined with motors, pinions, and planetary

gears. Functions and parts of the mounting structure - such as attached bearing

rings - can be integrated.

IMO Slewing Rings can be

used in a variety of applications

IMO Slewing

Rings are used in numerous applications as machine elements that can

simultaneously transmit axial and radial forces, as well as tilting moments.

The application spectrum ranges from large triple-row roller slewing rings for

tunnel construction to small ball slewing rings for medical technology.

However, IMO slewing rings are used in the bottling and filling industry,

opencast mining, bulk handling, and transport engineering. In the field of

renewable energies, IMO blade bearings, yaw bearings, and main bearings are

used in wind turbines or as rotor blade bearings in tidal stream systems.

Below, you can find out about product details for your application.

DISCOVER YOUR PERFECT IMO SLEWING RING AT VHS HYDRAULIC COMPONENTS

The IMO Ball Slewing Rings feature:

·

Single or double row

·

Four-point raceway geometry

·

Enables robust constructions for harsh operating

conditions

Ball

diameter

12 to 80 mm

The IMO Roller Slewing Rings feature:

·

Single-row, double-row, or triple-row

·

Top load with really small installation space

·

Top requirements for even load distribution.

Roller

diameter

10 to 100 mm

The IMO Ball-Roller Combination Slewing Rings feature:

·

Combination of roller and ball slewing rings

·

Used for dominant axial force and low radial

loads/tilting moments

Ball diameter25 to 80 mmRoller diameterto 100 mm

WE ARE AN IMO DISTRIBUTOR

Enquire about IMO Slew

Drives and Slewing Rings at VHS Hydraulic Components

VHS Hydraulic Components

is an IMO UK distributor. VHS Hydraulic Components supplies IMO Slew Drives,

including IMO Slew Drives WD Series (WD-L & WD-H) and IMO Slew Drives SP

Series (SP-I & SP-H), as well as IMO Slewing Rings, including IMO Ball

Slewing Rings, IMO Roller Slewing Rings and IMO Ball-roller Combination Slewing

Rings.

To enquire about IMO Slew

Drives and IMO Slewing Rings, please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net/

No Minimum Order

No Minimum Order