At VHS Hydraulic Components and as part of our hydraulic group, including Neilson Hydraulics and Parmafluid, we are specialists in the designing and manufacturing of Hydraulic Powerpacks.

As a hydraulic group we have been designing, building, installing and commissioning hydraulic power units for over 30 years, covering a wide range of applications across a variety of sectors.

We manufacture custom-made hydraulic power units (HPU) than can be built strictly in accordance with client specifications. We are able to provide you with a complete hydraulic solution from ‘concept to completion’. We can provide repeat hydraulic power units, as well as hydraulic power units for specialist projects.

We work in a variety of industry sectors, including oil, gas, petrochemical, marine, offshore, material handling, recycling, agriculture, rail, quarrying, construction, injection moulding, steel, mining and water authority.

We have strong technical abilities in CAD, SolidWorks, system controls and hydraulic circuit design.

Specialists in designing and building Hydraulic Power Units

- Specialists in the design, build, manufacture, installation and commissioning of hydraulic power units.

- Produce standard hydraulic power units, including budget, mid-range, medium pressure and high pressure.

- Offer custom-made hydraulic power units to meet client specifications for specialist and repeat projects.

- Vast expertise in a variety of industry sectors.

How we design a power pack to meet your needs:

Hydraulic power packs are essential components in hydraulic systems. They are designed to provide hydraulic power to various machines and devices. In this article, we will discuss the process of designing and manufacturing a hydraulic power pack.

Design Process

The design process of a hydraulic power pack involves several steps, as follows:

- Requirement Gathering: The first step in the design process is to gather the requirements for the hydraulic power pack. This involves understanding the application, the load requirements, the environment in which it will be used, and any other special requirements.

- System Design: The next step is to design the hydraulic system. This involves selecting the right hydraulic components, such as pumps, motors, valves, and cylinders, based on the application and load requirements.

- Sizing Components: Once the components are selected, they need to be sized according to the load requirements. The sizing of components is critical to ensure that the hydraulic power pack can handle the load and operate efficiently.

- Circuit Design: The hydraulic circuit is designed based on the selected components and sizing calculations. The circuit design ensures that the hydraulic power pack can operate efficiently and meet the application requirements.

- Layout Design: The layout design involves designing the hydraulic power pack's physical layout. The layout design ensures that the hydraulic power pack can be installed and maintained easily.

- Electrical Design: The electrical design involves selecting and sizing the electrical components required to operate the hydraulic power pack, such as switches, relays, and sensors.

- Control System Design: The control system design involves designing the control system that operates the hydraulic power pack. This includes selecting and sizing the control components and designing the control software.

- Testing and Validation: Once the design is complete, the hydraulic power pack is tested and validated to ensure that it meets the application requirements.

Manufacturing Process

The manufacturing process of a hydraulic power pack involves several steps, as follows:

- Material Procurement: The first step in the manufacturing process is to procure the materials required for the hydraulic power pack. This includes hydraulic components, electrical components, and structural components.

- Component Assembly: The hydraulic components are assembled according to the hydraulic circuit design. This involves connecting the pumps, motors, valves, and cylinders according to the circuit diagram.

- Electrical Assembly: The electrical components are assembled according to the electrical design. This involves wiring the switches, relays, and sensors according to the electrical diagram.

- Control System Assembly: The control system components are assembled according to the control system design. This involves assembling the control components and programming the control software.

- Structural Assembly: The structural components are assembled according to the layout design. This involves assembling the frame, tank, and other structural components.

- Quality Control: Once the hydraulic power pack is assembled, it undergoes quality control checks to ensure that it meets the design specifications.

- Testing: The hydraulic power pack is then tested to ensure that it operates efficiently and meets the application requirements. Testing involves running the hydraulic power pack under load and monitoring its performance.

- Packaging and Shipping: Once the hydraulic power pack is tested and validated, it is packaged and shipped to the customer.

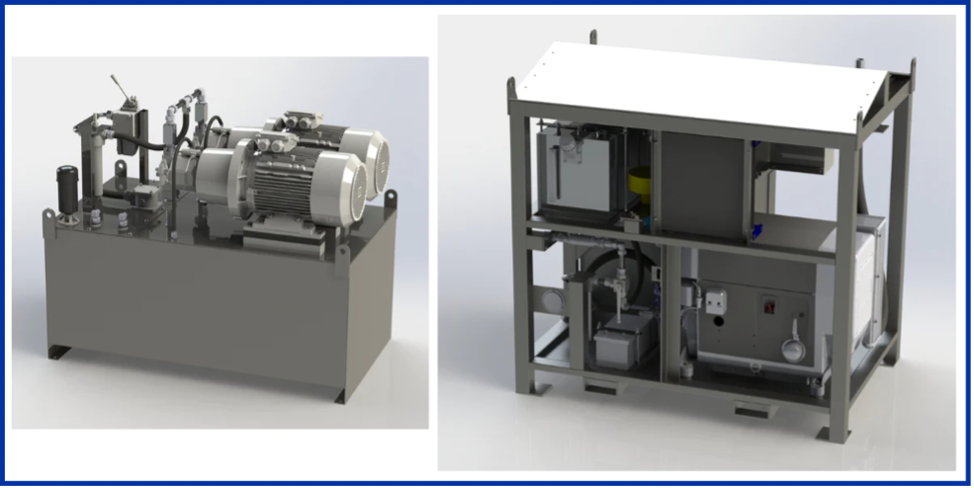

Examples of our hydraulic power unit portfolio:

15KW Motor Power Pack with a PLP30.38 PUMP (55 litres per minute) @165 bar.

‘Concept to Completion’

Conclusion

The process of designing and manufacturing a hydraulic power pack is complex and involves several steps. The design process involves gathering requirements, designing the hydraulic system, selecting and sizing components, designing the circuit, layout, electrical, and control systems, and testing and validating the design. The manufacturing process involves procuring materials, assembling components, performing quality control checks, testing, packaging, and shipping. The process requires expertise in hydraulic, electrical, and control systems, as well as manufacturing and quality control.

To enquire or speak to our technical team about all your hydraulic solutions please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net

No Minimum Order

No Minimum Order