At VHS Hydraulic Components and as part of our hydraulic group with Neilson Hydraulics, we offer a comprehensive hydraulic cylinder repair service to get you back up and running quickly and efficiently. Our team of experts are highly skilled in repairing and maintaining cylinders used in a wide range of applications, from automotive to industrial and agricultural.

We understand that hydraulic cylinders are a critical component in the operation of any system, so we use only the highest quality parts and components to make sure the job is done right the first time. Our experts will thoroughly inspect the cylinder and identify any faults or weak points, then replace any worn or damaged parts.

Our cylinder repair services also include leak testing, pressure testing, and performance testing for your hydraulic system, to ensure optimal performance and reliability. We also offer troubleshooting services to identify any potential problems with your system and suggest effective solutions.

At VHS Hydraulic Components, we understand that time is of the essence, so we work hard to get your cylinders back to you as soon as possible. We use only the highest quality parts and components, so you can be sure you’re getting the best service available. With our commitment to quality and customer service, you can be sure that you’ll get the best value for your money.

Contact us today to learn more about our hydraulic cylinder repair services.

Our In-House Hydraulic Cylinder Repair Overview:

We offer:

- a quick, efficient turnaround on repairs of general hydraulic cylinders

- providing a detailed quotation

- test certificate and

- serial number

Hydraulic Cylinder Overview

Hydraulic cylinders are vital in many industrial machines, and repairs to them are often unavoidable. Hydraulic cylinders work by using pressurized hydraulic fluid to create a force in a reciprocating linear motion. This motion is used to power a variety of industrial machines, from manufacturing equipment to construction machinery.

There are several different types of hydraulic cylinders, each used for different purposes. The most common type is the single-acting hydraulic cylinder, which uses hydraulic fluid to move a piston or rod in one direction. This type of cylinder is often used to power simple tasks such as lifting or pushing. On the other hand, double-acting hydraulic cylinders use hydraulic fluid to power a piston or rod in both directions. This type is commonly used to control more complex tasks, such as opening and closing valves or controlling the speed of a machine.

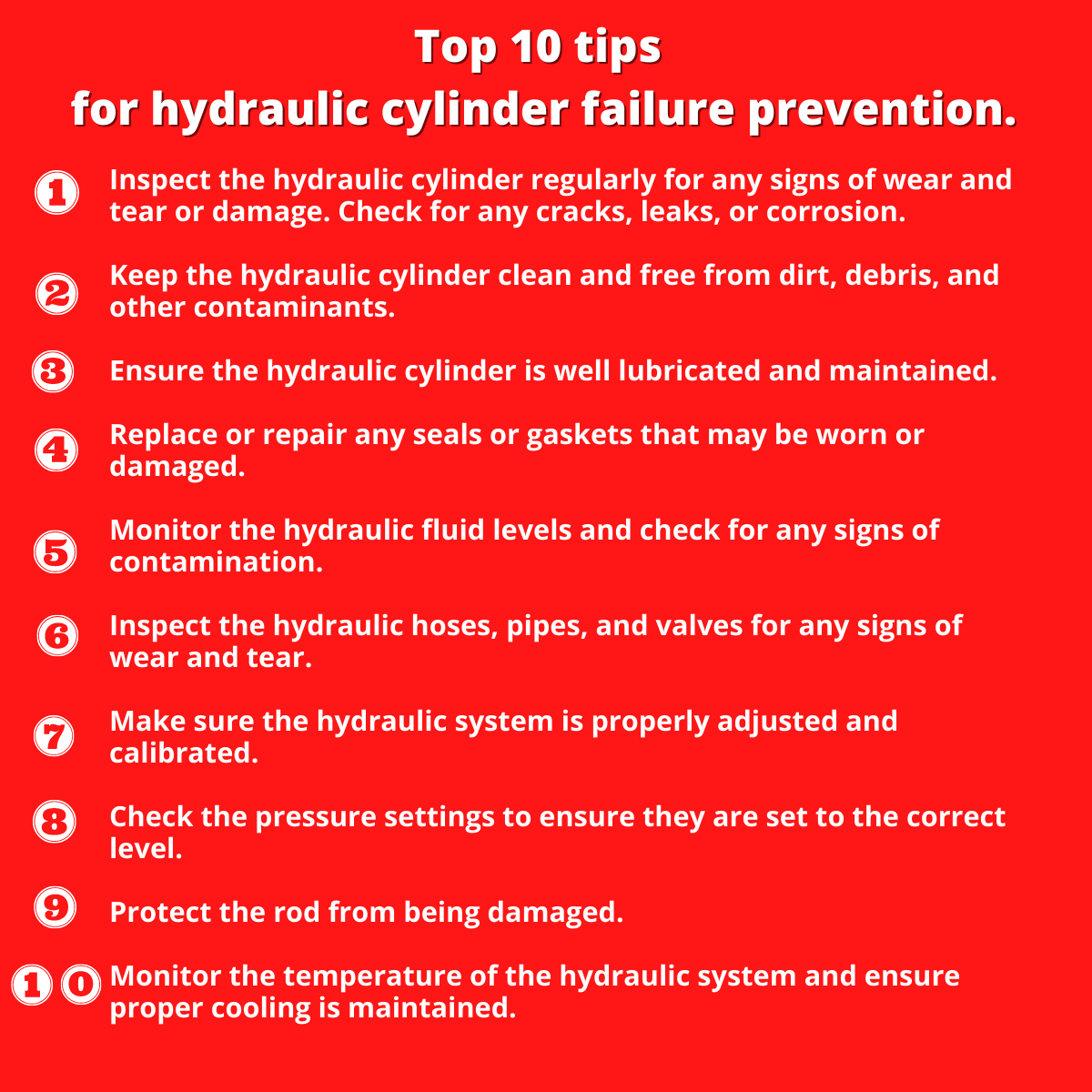

Top 10 Tips for Hydraulic Cylinder Failure Prevention

Hydraulic Cylinder Repair Brief Overview

When repairing a hydraulic cylinder, the first step is to identify the type of cylinder and its purpose. Once the correct type and purpose of the cylinder is determined, the next step is to inspect the cylinder for any visible damage or defects. Common issues that can cause a hydraulic cylinder to malfunction include blockages in the lines, leaks in the seals, wear in the piston or rod, and contaminants in the fluid. Once any existing damage is identified, the necessary repairs can be made.

For single-acting hydraulic cylinders, this may involve replacing seals and gaskets, repairing or replacing the piston or rod, and flushing out any contaminants from the hydraulic fluid. Additional repairs such as replacing the hydraulic fluid and tightening bolts may also be necessary for double-acting cylinders.

Once all repairs have been made, the hydraulic cylinder should be tested to ensure that it is functioning properly. This can be done by pressing a button or pulling a lever to activate the cylinder and observe its motion. If everything is functioning correctly, the cylinder should move in the desired direction smoothly and without any jerking or stalling.

To keep a hydraulic cylinder functioning properly and reduce the chance of needing repairs, regular maintenance should also be conducted. This includes regularly checking for any signs of wear or damage, topping up the hydraulic fluid, and cleaning out any dirt or debris that may have built up over time.

Hydraulic cylinder repairs can be a tricky and time-consuming process, but with the right knowledge, tools, and patience, they can be completed successfully. With regular maintenance and care, your hydraulic cylinders.

Hydraulic Cylinder Stock

At VHS we do not just repair hydraulic cylinders, we stock a large volume of hydraulic cylinders. Most sizes are stocked up to 1 metre stroke to help prevent expensive downtime.

To enquire about our hydraulic cylinder repair services and stock, please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: www.www.hydraulic-components.net

No Minimum Order

No Minimum Order