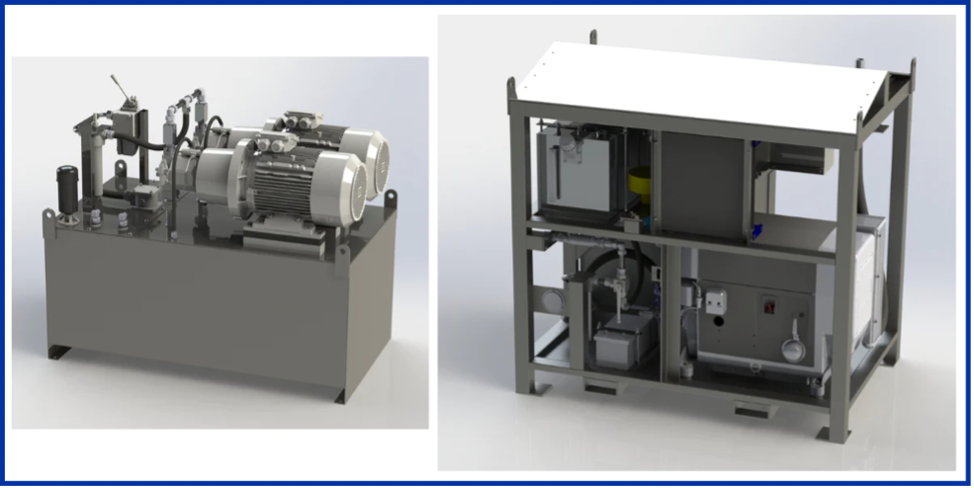

Hydraulic power packs serve as the beating heart of countless industrial applications, providing the necessary force to drive machinery, equipment, and systems with precision and efficiency. These compact yet powerful units house an array of components working in concert to generate hydraulic power, making them indispensable in a wide range of sectors, from manufacturing and construction to automotive and aerospace. However, like any mechanical system, hydraulic power packs require regular maintenance to ensure optimal performance and longevity. Below are ten tell-tale signs that indicate your hydraulic power pack may be in need of attention.

1. Unusual Noises

One of the most evident signs of trouble within a hydraulic power pack is the emergence of strange or excessive noises during operation. Sudden bangs, clangs, or whining sounds could indicate issues such as cavitation, worn-out components, or air ingress, all of which necessitate immediate inspection and maintenance.

2. Fluid Leaks

Fluid leaks are a clear indicator of potential problems within the hydraulic system. Whether it's visible leakage around seals, fittings, or hoses, or the presence of hydraulic fluid pooling beneath the power pack, addressing leaks promptly is crucial to prevent fluid loss, contamination, and potential system failures.

3. Decreased Performance

A decline in the performance of the hydraulic power pack, manifested as reduced speed, power output, or efficiency, is a red flag that maintenance may be overdue. This could stem from various factors, including worn-out components, fluid degradation, or insufficient pressure, all of which require thorough diagnosis and remediation.

4. Overheating

Excessive heat buildup within the hydraulic power pack can spell trouble for its components, leading to premature wear, fluid degradation, and potential system failures. Monitoring temperature levels and addressing overheating issues promptly through measures such as improving cooling efficiency or replacing worn-out components is essential to prevent damage and ensure continued operation.

5. Unresponsive Controls

If the controls of the hydraulic power pack become unresponsive or erratic, it could signal underlying issues such as electrical faults, sensor malfunctions, or hydraulic system failures. Conducting a comprehensive inspection of the control system and associated components is crucial to identify and rectify the root cause of the problem.

6. Vibrations or Oscillations

Excessive vibrations or oscillations during operation can indicate misalignment, imbalance, or mechanical issues within the hydraulic power pack. These vibrations not only compromise the performance and efficiency of the system but also pose safety risks to personnel and surrounding equipment. Addressing the root cause through proper alignment, balancing, or component replacement is essential to mitigate these risks.

7. Contaminated Fluid

Contaminated hydraulic fluid, characterized by discoloration, cloudiness, or the presence of debris or foreign particles, poses a significant threat to the integrity and performance of the hydraulic power pack. Regular fluid analysis and filtration are essential to remove contaminants and maintain fluid cleanliness, thereby prolonging the life of system components and ensuring reliable operation.

8. Pressure Fluctuations

Fluctuations in hydraulic pressure, whether sudden spikes or drops, can indicate problems such as pump wear, valve malfunctions, or fluid leakage within the hydraulic power pack. Monitoring pressure levels and conducting thorough diagnostics are essential to pinpoint the root cause and implement appropriate corrective measures to restore optimal pressure regulation.

9. Increased Energy Consumption

A noticeable increase in energy consumption by the hydraulic power pack could signify inefficiencies within the system, such as leakages, pump inefficiencies, or excessive friction. Conducting an energy audit and identifying areas for improvement, such as optimizing component selection or enhancing system design, can help reduce energy consumption and operating costs while improving overall performance.

10. Odor or Discoloration

Unusual odors emanating from the hydraulic power pack, such as burnt or acrid smells, along with discoloration or degradation of system components, could indicate overheating, fluid contamination, or chemical breakdown. Addressing these issues promptly through fluid analysis, component inspection, and corrective maintenance is essential to prevent further damage and ensure safe and reliable operation.

As a hydraulic group, VHS Hydraulic Components and our sister company Neilson Hydraulics, specialise in the design, build, manufacture, service, installation and commissioning of hydraulic systems.

We manage the whole project from concept to completion and understand all aspects of the complete system build. Systems are designed, fabricated, assembled, built and tested by our competent staff in our workshop.

We have vast expertise from producing highly complex and technical hydraulic systems to basic hydraulic systems to overhauling existing hydraulic systems. We regularly produce repeat and bespoke hydraulic systems for our customers.

Specialists in Hydraulic Systems from concept to completion:

- Complete system design, build, manufacture, service, installation and commissioning of hydraulic systems

- Vast expertise of producing basic to highly complex / technical hydraulic systems.

- Modification and upgrading of existing systems

- Fault finding, troubleshooting and service

Conclusion

Maintaining the health and functionality of hydraulic power packs is paramount to the smooth operation of industrial machinery and systems. By remaining vigilant for the signs outlined above and conducting regular inspections and maintenance, operators can mitigate risks, prevent costly downtime, and prolong the service life of their hydraulic power packs. Investing in proactive maintenance measures not only safeguards equipment and personnel but also ensures the continued efficiency and productivity of hydraulic-powered applications across diverse industries.

To enquire about all your hydraulic requirements, please contact VHS Hydraulic Components on: 0114 276 4430 / E: info@www.hydraulic-components.net or visit our website at: https://www.hydraulic-components.net/

No Minimum Order

No Minimum Order